I’ve been checking out parts lists and prices for DIY CNC routers. After some research, I’ve decided to convert my Prusa Mendel i2 to a small, very cheap CNC engraver, So I could get a feel for them and work out if it would be worth making a full size one.

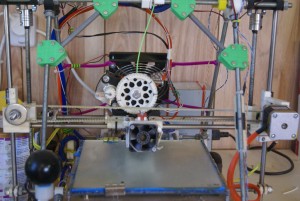

Below is what I had to work with. You may notice the extra braces on the top corners – the green parts. There is other extra supports on the board it’s screwed on to, to make it more ridged than usual.

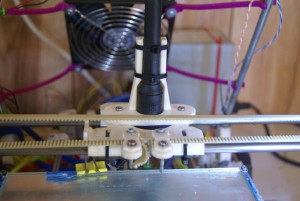

I found a few mounts on thingyverse, but I have an old Ozito rotary tool. The flexi shaft has different dimensions than the Dremel, so I created my own mount for it: Ozito_FlexMount

I did a test print @ 20% fill and 1 perimeter, but it wasn’t strong enough. So I changed it to 70% fill – Excessive? No, when using the 20% fill, the flexi shaft had too much movement.

Final hardware changes:

The way a CNC router works is the reverse of the way most 3D additive printers work. Mainly – a CNC router usually cuts an object from a larger material and starts from the top. 3D additive printers build the objects form the bottom. The printer needs the Z axis reversed to be of any use. Rather than recompiling the Sanguinololu firmware (the controller I’m using), I chose a simple software mod that should have similar a affect. I did have to recompile the firmware later to get the eeprom to work.

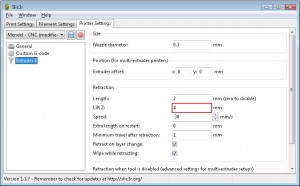

Repetier-Host uses Slic3r (in Windows) to create the G-Code for the printer. The cutter needs to plunge into the material, cut, then lift back out before moving to the next cut. This is done by using “Lift Z”:

Now to reverse the Z Axis: Config, Printer Settings, tick “Invert Directions in Controls for” Z-Axis. This will only work when engraving or cutting basic shapes with 90 degree sides.

Test Engraving Samples:

Caveats so far:

- You cant cut panels, unless you create inverted objects, remember the software still thinks it’s building the object, not cutting it out from around the external edges. Repetier-Host and Slic3r weren’t made for this. Still looking for an alternative, that is as easy to use.

- Tool changing could be a little easier.

I’ve not used Lift-Z before so I’m having issues where it tries to move too quickly, and all I get it a small amount of motion and the motors buzzing (missing steps). Still looking for the solution. This forum post looks to be the answer.- Fixed by adding custom G-Code to Slic3r: “M203 X500 Y500 Z5 E25” which it does enforce, even though it’s the same values that are hard coded into the firmware.

This is still a work in progress, and to get the most out of it, I’ll need different software.

UPDATE – MID 2015

Took conversion off when I needed to print the fascia for the Internet Radio project. TBH it wasn’t the best anyway. Had a few directional issues and perhaps rather than using Repetier-Host with Slic3r, maybe use Slic3r by itself.

Cheers

Great post.